Description

1. Product Information

| Size (T x W x L) | Pattern | System | Edge | Package | YC Code |

| 9mmx300mmx600mm | Travertine | Double Layer | Square | 18pcs/ctn | PSAAD101 |

| 12mmx300mmx600mm | Rib101 | Double Layer | Square | 18pcs/ctn | PSAAD102 |

2. Physical Data Summary for 9mm thickness

| Physical Properties | Test Method | |

| Moisture Content (%) | 1.50% | JIS A 6301 |

| Mudulus of Rupture(kgf/cm2) | 25kgf/cm2 | JIS A 6301 |

| Non Combustibility | As approved by th Japanese Minister of Construction under the approval No. 1021 from Japan | |

| Fire Propagation Test | Class 0 | BS476 Part 6 |

| Flame Spread | Class 1 (0-25) | ASTM-E84 |

| Class A | U.S. Federal Specification SS-S-118B | |

| 20 | Underwriters Laboratories Inc. | |

| Class 1 | BS476 Part 7 | |

| Thermal Conductivity | 0.051 kcal/mh °C | JIS A 1412 |

3. Physical Data Summary for 12mm and 15mm thickness

| Physical Properties | Test Method | |

| Moisture Content (%) | 2.00% | JIS A 6301 |

| Modulus of Rupture(kgf/cm2) | 17kgf/cm2 | JIS A 6301 |

| Non Combustibility | As approved by the Japanese Minister of Construction under the approval No. 2026/BS476 Part 4 from Japan | |

| Fire Propagation Test | Class 0 | BS476 Part 6 |

| Flame Spread | Class 1 (0-25) | ASTM-E84 |

| Class A | U.S. Federal Specification SS-S-118B | |

| 20 | Underwriters Laboratories Inc. | |

| Class 1 | BS476 Part 7 | |

| Thermal Conductivity | 0.045 kcal/mh °C | JIS A 1412 |

4. Noise Reduction Coefficient (NRC)

NRC is the average sound absorption while the sound strike the panel on one side and

transmitted from the other side. NRC is a single number ranging between 0 – 1.0

measured at frequency 125Hz, 250Hz, 500Hz, 1000Hz, 2000Hz and 4000Hz under ASTM C 423

standard.

| Frequency (Hz) | Noise Reduction Coefficient (NRC) | ||

| 9mm | 12mm | 15mm | |

| 125 | 0.29 | 0.33 | 0.36 |

| 250 | 0.26 | 0.26 | 0.28 |

| 500 | 0.38 | 0.50 | 0.52 |

| 1000 | 0.62 | 0.63 | 0.64 |

| 2000 | 0.78 | 0.80 | 0.80 |

| 4000 | 0.95 | 0.95 | 0.97 |

| Average NRC | 0.48-0.53 | 0.53-0.57 | 0.55-0.60 |

5. Ceiling Attenuation Class (CAC)

CAC is the ability of a ceiling tile to prevent the transmission of sound between rooms with a

common ceiling space. Therefore, it rates a ceiling’s efficiency as a barrier to airborne sound

transmission between adjacent closed offices under ASTM E 413 standard.

| Frequency (Hz) | dB (Decibel) | ||

| 9mm | 12mm | 15mm | |

| 125 | 17 | 18 | 20 |

| 250 | 20 | 28 | 29 |

| 500 | 23 | 34 | 36 |

| 1000 | 28 | 37 | 39 |

| 2000 | 32 | 38 | 40 |

| 4000 | 30 | 38 | 40 |

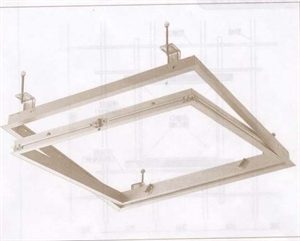

6. Installation Guide

Lay over back of DAIKEN board by Latex Glue in quantity of 45-55 grams / pcs, after that

shooting air nail on DAIKEN surface together with gypsum board in quantity of 30-45 nails/pcs

by laying down DAIKEN board in Ashlar pattern.

7. Why have to use DAIKEN acoustical ceiling tile?

– ASBESTOS FREE: DAIKEN is asbestos free products. Use of Asbestos, can cause

cancer and an adverse effects on the human body and the environmental.

– OUTSTANDING FIRE RESISTANCE: DAIKEN is not only non-combustibility, but also

less likely to emit toxic gas or smoke, or to melt, break, or become deformed under

normal fire conditions, protecting ceiling areas from fire.

– DAIKEN is only brand in the market provide ADHESIVES AND NAILS SYSTEM

for drywall ceiling, with joint after laying on the ceiling.

8. Guarantee

DAIKEN guarantees sagging for 10 years after installation under below conditions:

8.1 DAIKEN must be installed after cement and gypsum work has been dried and finished.

8.2 DAIKEN must be installed after work has been done such as door, window and

electronic wire installation.

8.3 DAIKEN installation shall be done under the conditions of relative humidity not more

than 80%

8.4 DAIKEN shall be installed at good ventilation area.